|

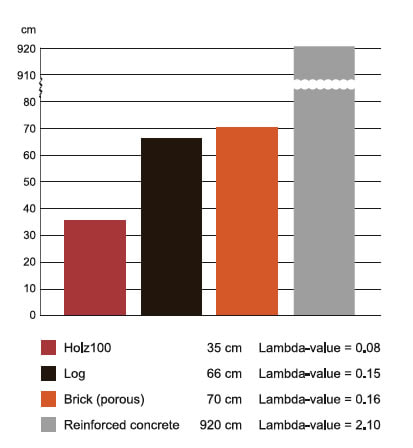

Wood naturally insulates, stores and buffers by nature - every wooden house has the potential to become an oasis if the wood is installed unadulterated. Thanks to its patented design, Holz100 doubles the efficiency of full or glued wood, thus keeping the world record in thermal insulation. This makes energy-efficient housing, passive houses without insulation, and complicated building technologies possible. Yup, you'd better believe it - there are even Holz100 buildings that are built without insulation! We know what architects will ask right away when we tell them our material has an R value of 2.4 per inch: "How is it possible for 100% pure, natural wood to achieve that insulation value on its own?" and here is our answer: The Thoma Holz100 Thermal walls consist of layers of cross-laminated wooden boards with a thickness of 20mm to 80mm connected by wooden dowels. What’s different are the grooves milled into individual layers of wood. The grooves milled into the layers of wood (integrated structural insulation) function within the Holz100 wall to laminate as microscopic air cushions without circulation, and reduce the wall’s thermal conductivity which results in a substantially improved thermal insulation. At their full static load capacity, the Holz100 Thermal walls show parameters otherwise reserved solely to insulation materials (lambda value =0.079 W/m²K). It also makes it possible for external walls to have a very high energy standard with only a little additional thickness for insulation. Our research work combines excellent technical parameters with a background of building-specific physical properties, which at least minimizes the building cost. Here are some tests we took: 1. To achieve a thermal rating of U = 0.3 W/m2K, which is the current European norm aspired to build without insulation, would have to use the following wall thicknesses: Reinforced concrete: 726 cm Average brick: 60 cm Conventional timber & glue-laminated wood products: 47 cm Holz100: 27cm 2. This diagram shows how much material is needed to achieve the U-value of 0.22 W/m²K: Conclusion: an average Holz100 home only needs 1/3 of the heating system compared to a traditionally insulated home with the same R value and requires only 3/5 of wall thickness (laminated commercial timber) to achieve the same thermal rating. Holz100 is the only known construction methodology that can be built in multiple stories without additional insulation. Passive house standards are achieved by using 35cm of Holz100 (U-value approx. 0.22). This energy saving phenomenon is possible by routing small air-pockets between the timber layers in the solid wood elements. Wood also acclimatizes a building more efficiently. Not only in winter when it acts as a heat conductor but during summer too. It is thermally slow and more effective than any other building material. This led us to build more and more roofs with solid wood panels in warmer areas which achieved much better ratings than with roof trusses, because they acted like wood frame walls. This is only 1 out of 12 great benefits of Holz100! See what other benefits make Holz100 an unparalleled multi-purpose building solution for healthier, greener, and safer living spaces.

1 Comment

Witold

7/15/2019 03:53:08 am

It is true that normal reinforced concrete will need to be almost 10 meters to achieve stated insulation. The thermal mass will also make it very stable,. but also phase shifted. However.

Reply

Leave a Reply. |

AuthorHolz100 Canada Inc. Archives

July 2019

Categories

All

|

HoursMon - Fri.

9:30am - 4:30pm |

Office |

President FRANK GHAHREMANI(416) 725-6747

|

RSS Feed

RSS Feed