|

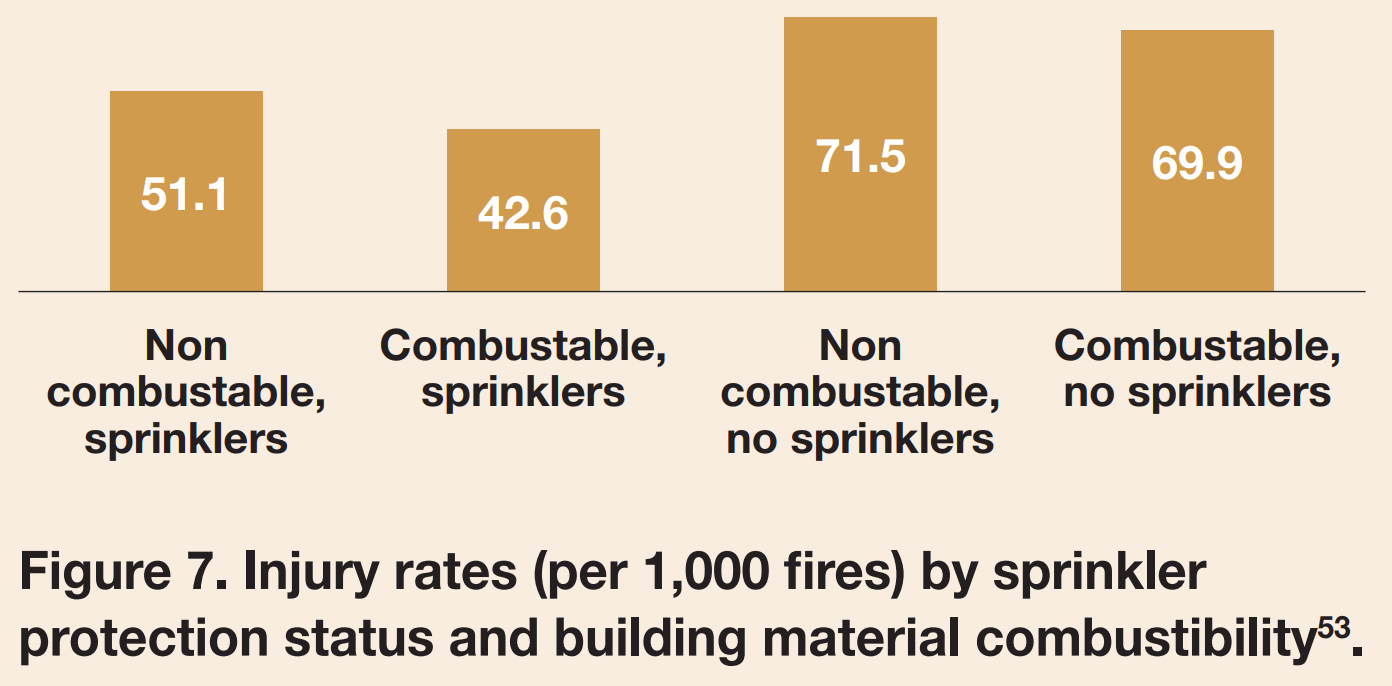

A common concern raised in regard to the use of wood as a building material is whether or not there is an increased risk of fire. Engineers and fire researchers today have a significant body of knowledge of how timber constructions perform in fire. The structural stability of timber is well understood and importantly it is predictable, allowing timber constructions to be created that meet the same fire safety codes as steel and concrete buildings. * Gerard, R., Barber, D. & Wolski, A. . (The Fire Protection Research Foundation, 2013). Heavy timber constructions have an inherent level of fire resistance. This resistance increases with the thickness of the wooden elements because when timber is exposed to fire the outer layer burns and turns to char. Charring creates a protective layer that acts as insulation and delays the onset of heating for the cold layer below. With continued exposure to fire the char layer grows, increasing the insulation and slowing down the burning rate, providing greater time for escape or intervention. An additional benefit to heavy timber is the ease of repair after a fire. The charred sections can visually be assessed and evaluated for residual capacity, and the damaged timber can then be cut away and replaced. This is in contrast to steel, which buckles under extreme heat. In light timber frame constructions the walls and floors are typically encased in non-combustible gypsum plasterboard to provide protection from fire. This provides the same level of fire resistance as a completely non-combustible material. * Buchanan, A. . (National Institute of Standards and Technology, 2014) Just because steel is a non-combustible material does not mean it is unaffected by fire. The thermal conductivity of steel is significantly greater than wood (200-1000 times more). This creates a thermal bridging effect, allowing heat from a fire in one part of a building to spread rapidly to other parts. Fire can also raise the temperature of steel enough to compromise its strength, with a reduction in its load carrying capacity by one third when heated above 540°C causing beams to buckle and floors to collapse. * Maxim, P., Plecas, D. & Clare, J. . (University of the Fraser Valley, Centre for Public Safety & Criminal Justice Research, 2013) A study that examined the rate of injury from hotel, motel and aged care home fires in America and Canada from 1980 to 1998 found that the presence of sprinklers had a greater impact than the combustibility of the building material (Figure 7 below). In fact sprinkler systems have been shown to be one of the primary factors in limiting fatalities and fire damage in structures of all types. * Richardson, L. R. Fire losses in selected property classifications of nonresidential commerical and residential wood buildings. Part 1: Hotels/ motels and care homes for aged. 31, 97–123 (2007). * Frangi, A. & Fontana, M. Fire Performance of Timber structures under Natural Fire Conditions. in 8, 279–290 (2005).

8 Comments

The first serious issue that Dr. Erwin Thoma came across in Germany was fire protection. In the 1970s and 1980s, wood houses were not allowed to be built with more than one floor. It was believed to be too dangerous because timber would burn quickly. Dr. Thoma decided to attain a fire safety certificate at the IBS Institute. It is one of the best known institutes of its kind in Europe, and it has the largest furnace for fire testing in Europe. A manager of the institute said, “It is a wooden wall, so let’s try to run the F30 test and see how it does.” This test examines whether a wall can withstand a flame of 1000 degrees on one side for 30 minutes. Dr. Thoma had initially claimed that although made of wood, Holz100 was a completely different structure and asked for them to examine how long the wall would last beyond F30. In response, the manager looked at Dr. Thoma as if he were an idiot and replied, “I said F30”. Dr. Thoma insisted, and the manager replied, irritated: “Listen, I have been working at the Institute for many years, and I have tested everything one could test in the timber industry. You should be glad if it can even withstand the F30 test. It will definitely not last any longer.” Finally, Dr. Thoma offered to pay for every minute of the test and the manager agreed, shook his head, and started the test. After 122 minutes, there was a strange sound. It turned out that the tank ran out of oil. Following this incident, the institute carried out the test at its own expense and in the end, Dr. Thoma received a F180 certificate. It turned out that after three hours of treating a Holz100 wall with a 1000 ° flame, the temperature on its other side rose only by 1.8° C. The same treatment of a reinforced concrete wall would have caused the temperature on the opposing side rise to 600° even after 20-30 minutes and everything would start to burn. Because of the heat, the concrete begins to crack in layers and release the rebar rods which then melt. It may seem unbelievable, but even a thick tree trunk thrown into the fire will often remain unburned, while the fire eventually fades and dies out. Only some of its surface will be charred as a result. When the source of fire disappears, the trunk stops burning as well. For wood to burn well, it must be cut into small pieces and surrounded by air. Today, Dr. Thoma's firm builds certified firewalls made of wood for industrial needs. "Safety is a cheap and effective insurance policy." - Author Unknown The European standard in high-tech woodblock and frame buildings (with normal, average wall, ceiling and roof thicknesses) is maximal F30. This means that the building element resists a flame at 1,000 degrees Celsius for 30 minutes. Holz100 elements reached top ratings of up to F180! This means six times safer than the usual reinforced concrete or brick walls offer. The ceiling ratings are even better. Why? Wood burns well when it is thin and in contact with plenty of air. However, a thick block of wood hardly burns at all. It chars fairly slowly, approximately 0.5-0.7mm per minute. In a Holz100 house, every ceiling, wall and floor is a thick, fire-resistant block of wood that serves as firewalls. Thoma Holz100 (40cm wall): REI 120 minutes or F90 fire resistance Thoma Holz100 (17cm wall): REI 60 minutes or F60 fire resistance While flame testing reinforced concrete walls, the cold side of the wall (which was not directly exposed to the flame) was showing in some areas a +400 degrees Celsius temperature rise after only 30 minutes. This happens because the reinforcement iron inside the concrete turns glowing hot and conducts the heat rapidly throughout the whole wall element. While flame-testing a Holz100 wall element, the hottest spot on the cold side after 90 minutes was maximal only +1.8 degrees Celsius higher than the temperature taken in the start of the test. Wood is a warmth shield and even after hours of external flame testing and heat, its innermost is quite unchanged. This is incredibly important for safety reasons, particularly in large buildings. Many fires expand faster via heat than flames. Even if this sounds incredible, it has been proven that engineered wood is safer than concrete. "Most fire deaths are not caused by burns, but by smoke inhalation. Often smoke incapacitates so quickly that people are overcome and can’t make it to an otherwise accessible exit. The synthetic materials commonplace in today’s homes produce especially dangerous substances." - National Fire Protection Association Since Holz100 is 100% pure wood, its inhabitants need not worry about toxic fumes. With its singular natural component combined with structural capacities akin to a firewall, it is the ultimate fire-resistant building system. |

AuthorHolz100 Canada Inc. Archives

July 2019

Categories

All

|

HoursMon - Fri.

9:30am - 4:30pm |

Office |

President FRANK GHAHREMANI(416) 725-6747

|

RSS Feed

RSS Feed