|

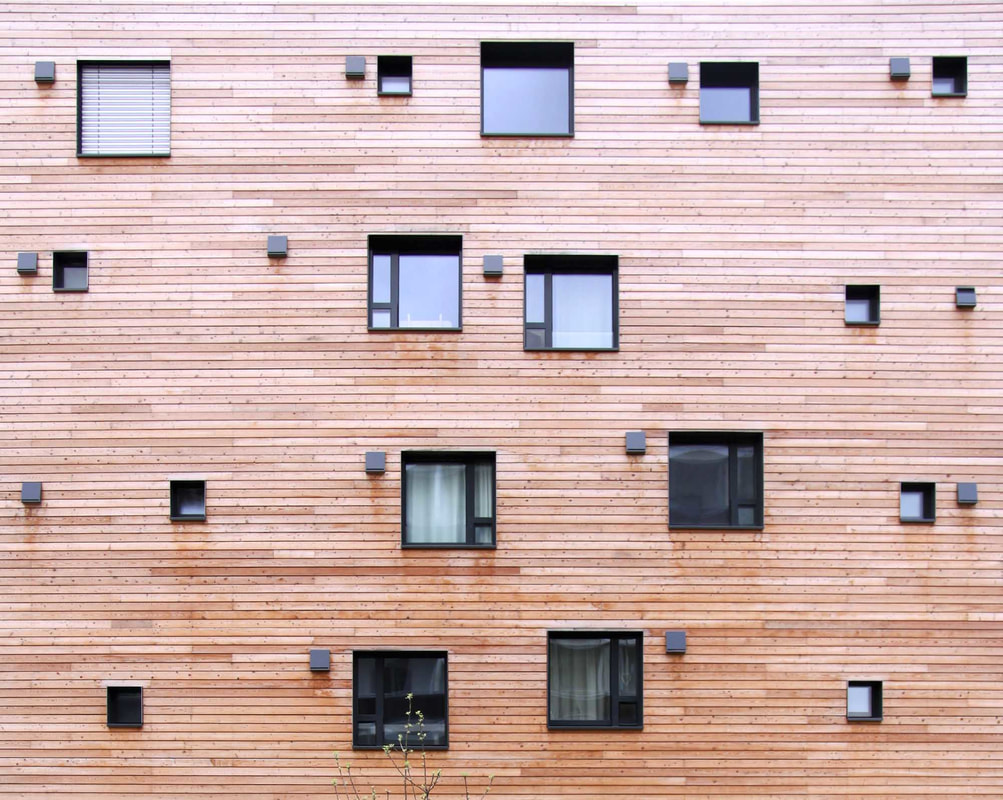

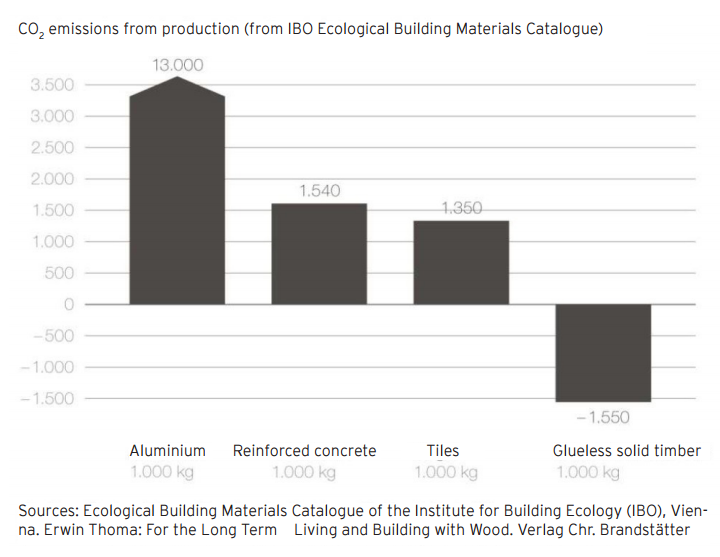

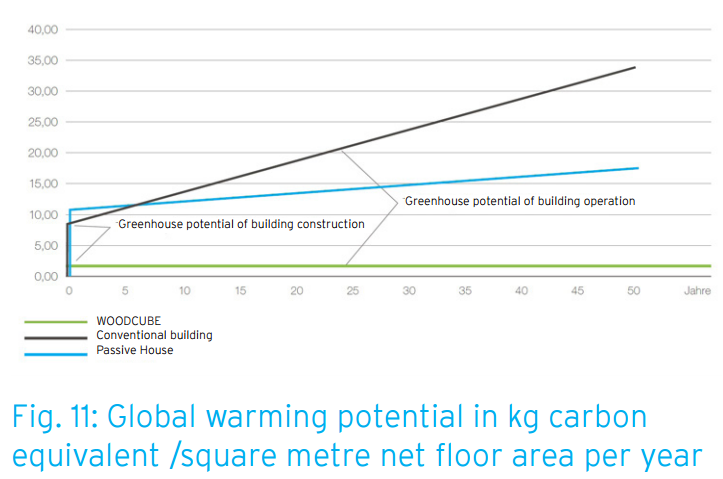

"GREEN" REDEFINED; where wood meets advanced technology. The “WOODCUBE” is the first carbon-neutral multistory residential block in building class 4 to be constructed without toxic substances and to have the wood completely visible from the inside, only achieved by using Thoma Holz100 as its main building system. As such, it constitutes a new timber construction system for urban settings that is resource-conserving, healthy, and long-lasting. WHAT IS A 'SMART MATERIAL HOUSE'? “Smart materials” are materials, material systems, and products that can be derived from them that behave not in a static but a dynamic way, in contrast to conventional building materials. In other words, because of their nature, these materials react to changing environmental conditions and adapt to them. The building shell is one of the most crucial elements in this respect: the use of smart materials in the façade can enable energy and material flows to be improved and kept as low as possible, since a large proportion of these materials draw energy directly or indirectly from the surrounding environment. Smart materials are active, with a transformative character. They respond to changing environmental conditions. A “Smart Material House” is a new form of residential building in which adaptable architectural designs can be combined with intelligent technologies and construction materials. The building envelope is the central element of the energy exchange between inside and outside. It controls inflowing and outflowing energy streams and the circulation of material. Using smart materials and smart technologies, building envelopes can actively regulate energy and material flows. Since the beginning of the modern period, building services have been bundled away, centralised, and thus often rendered invisible. With the proliferation of smart materials, the material surface can itself become a medium carrying energy and information. CARBON NEUTRAL The "WOODCUBE" is a five-storey apartment building with a flexible number of apartments. The design demonstrates the possibilities of forward-looking solid timber construction. It largely avoids the use of non-renewable raw materials in both its construction and its operation. Energy and heat energy are carbon neutral and derived from renewable sources. The "WOODCUBE" project is the first time that an apartment complex has been built that does not emit any greenhouse gases over its life cycle, and is almost completely biologically recyclable. All of the construction materials were therefore checked for their carbon potential and biological compatibility in building. A sophisticated building services concept with central building control and smart metering supports the consistently low energy consumption. Compared with conventional buildings, approximately 8,500 tonnes of carbon were saved during the construction phase alone. PASSIVE HOUSE ENERGY STANDARDS By eliminating fire-protective encapsulation, the building components could remain visible on the inside. This meant that there was no need for additional coatings or protective structures, while the indoor climate benefits from a structure that is open to diffusion, with a higher heat storage capacity. The building’s structural properties also allow construction without thick insulating material. Nevertheless, this project has similar energy properties to those of highly insulated Passive Houses. The model energy properties demonstrated here, along with the actual energy consumption, come below the calculation values stipulated by lending institutions. This has resulted in a system component that brings sustainability, fire safety, and favourable energy properties together in synergy, while maintaining the strict single-material approach. This saves resources while ensuring a high level of efficiency. The Thoma Holz100 system, which was thermally optimised in collaboration with various experts, now makes it possible for the “WOODCUBE” to achieve the KfW-40 standard. As several studies show, the considerable advantages offered by the positive material properties of solid wood construction in terms of energy efficiency cannot be attained through conventional methods. The actual energy consumption is likely to be similar to that of a Passive House. If we look at the building’s energy requirement purely in terms of the numbers, it comes to 18 kWh/m2 per year, which is roughly equivalent to the Passive House standard. ABOVE-AND-BEYOND The “WOODCUBE” makes an outstanding contribution to sustainable building typologies, while venturing far beyond prevailing construction standards and the current discourse surrounding sustainability in architecture. It is worth noting that the project did not receive the German Sustainable Building Council (DGNB) Gold Seal. This would have been possible if a preliminary investigation had been carried out, as its consistent environmental focus would have met the sustainability criteria, with energy savings of up to 95 per cent. Nevertheless, the DGNB nominated the “WOODCUBE” for the 2013 German Sustainability Prize, which it shared with two other buildings. Wood has been used as a construction material for thousands of years. Through a smart approach and the use of highly modern technology, it has been transformed into a smart material that can define inner city housing construction. The “WOODCUBE”, developed as part of the IBA Hamburg 2013, is a prominent example of this approach.

0 Comments

Leave a Reply. |

AuthorHolz100 Canada Inc. Archives

July 2019

Categories

All

|

HoursMon - Fri.

9:30am - 4:30pm |

Office |

President FRANK GHAHREMANI(416) 725-6747

|

RSS Feed

RSS Feed